Comfort always holds the first place

FABRICS –The roof and sides are made of a heavy duty single skin 420g/ m2, 50% cotton and 50% acrylic fabric, which is water proof, breathable and rot-proof.

This fabric has several advantages: it's extremely breathable, so inside the tent is fresh and airy, unlike plastic-coated or resin-treated fabrics, which are non-breathable and therefore create lots of condensation, which is the main cause of moulds.

However the breathable nature of the fabric doesn't reduce it's impermeabilty to rain: on contact with water, the fabric weave swells and thickens; where sewing has occurred, the holes created by the needles swell and seal as does the thread used for stitching, whereas in plastic-coated fabrics, some permeable holes will still remain.

YARNS - A widely used, high-technology yarn, made of two different fibres: pure cotton outside, to swell on contact with water and fill the holes made by the needle plus a synthetic fibre core is used on the inside of the yarn to obtain a high strength seam.

COLOURS - The colours used since 1959, are for very practical reasons, including reducing the amount of light filtering through, by using medium grey on the roofs and dark blue for the sides.

PLATFORM BOARDS - The boards used for the tent base are made of a poplar plywood, which, thanks to its long fibres, is very resilient and hard-wearing. This 12 mm thick plywood has been developed for this particular application; the different layers are bonded together by the cross-overlapping method, following the wood grain to produce the products unique features.

The Air-Camping procedure includes, veneering both outside and inside of the tent base, by applying two 0.3 mm thick Silver-Quartz CHPL (Casework with High Pressure Laminate Finish) laminated sheets. The plywood, therefore, has a double protection: it is waterproof and water-repellent both outside and inside, does not absorb humidity, will not warp and prevents the formation of harmful mould.

METAL COMPONENTS - Both steel and aluminium are used in a combination that achieves a tent with strength, high resistance to wear and the elements, yet still maintain a light overall weight.

The metal elements used are first quality; being hot-galvanized during the mills' rolling process directly in the factory.

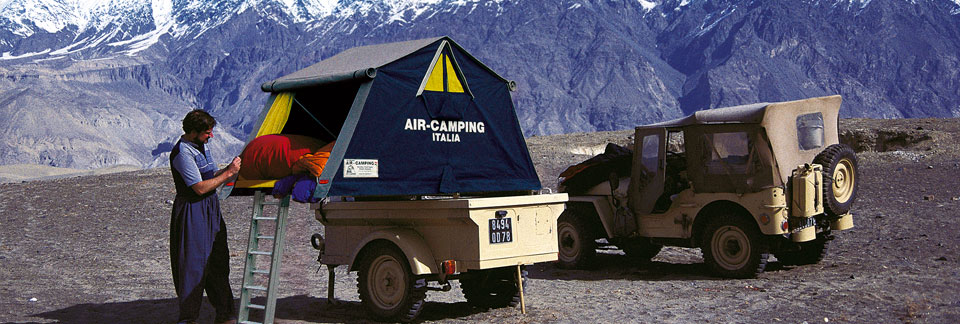

LADDER – Made of aluminium with steel stiffeners and extendable up to 2.30 metres. Quick release spring clips allow easy adjustment to the height of the ladder, and also keep it firmly locked in place on the tent base when in transit. With the tent in use, an automatic blocking mechanism prevents the ladder from slipping when being climbed, and allows for using the tent on uneven ground and smooth or slippery asphalts or pavements.

|

|

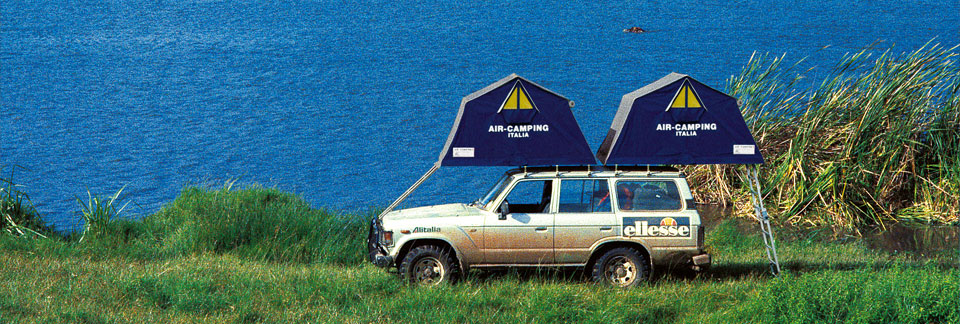

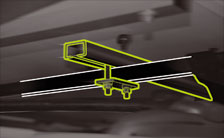

| Two mounting channels on the underside of the tent base, plus locking clamps, enable a quick installation of the tent on any vehicles roof bars or rack, they also allow you to customize the opening system: Standard or Explorer. The whole installation can be completed without further drilling or modification. |

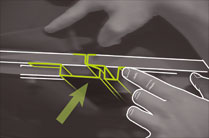

Exclusive hinge system allowing the two halves of the tent base to "lock" together. |

|

|

| The poles supplied create a practical awning. | Double opening. |

|

|

|

| Ladder anti-slip mechanism. | The removable inner elastic cords (supplied) make folding the fabric much simpler. | Two attached cam buckle straps keep the tent closed and compact, when sleeping bags or blankets have been left inside the tent. |