REPORT

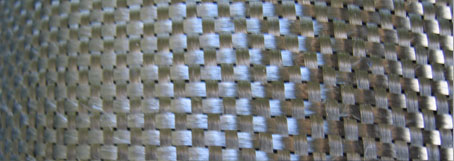

Shells in fiberglass

Fiberglass is a specific fibre threaded fabric, impregnated with liquid resins or polyester, often known as GRP from the English “glass reinforced plastic” (GFK in German).

Each individual Autohome roof tent is hand made, top quality. The very expensive resins, combined with various catalysts or accelerators, are all individually spread, using brushes and tail rollers, on the glass fibre fabrics laid beforehand on open molds: when the resins harden, they incorporate the glass fibre matting thus making fiberglass.

A laborious manual process: the specific materials are spread on a mould to get the shell shape, then further reinforcements in Kevlar are inserted in order to protect the Autohome roof top tents on the shell most critical parts.

Extensively used in the building sector, particularly in roof production, as well as industrial and civil coverings, fiberglass is extremely heat tolerant, keeping the internal space isolated (from heat or cold): a desirable feature for any roof tent.

Thanks to the use of fiberglass (as opposed to the common plastics used by Asian producers), Autohome roof tents provide absolute quality, not only in terms of weather resistance and soundproofing, but also in terms of weight and ease of repair in case of accidental damage, thus avoiding the expensive replacement of the entire unit.

The proven material quality of GRP means it’s ideally suited for the marine and vehicle industries, as boats and vehicle bodies require rigidity, strength and material stability…The best motorhomes, lorries and buses for example, with a vehicle body or components in fiberglass are considerably easier to repair than many other materials and composites such as plastic and ABS.

With its excellent lightness and strength, GRP is not only used in the marine sector, but also in the aeronautic industry, in the construction of wind turbines and in the aerospace industry, thanks to its extraordinary resistance to decompression. Autohome roof tents are designed and manufactured using the best materials currently available.

No pretence of reaching the Moon….at least for the time being!

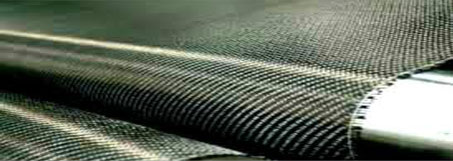

Details on carbon fiber

Shells in carbon fiber

The innovative and exclusive production of carbon fiber shells enables us to realize an exceptionally strong, yet lightweight tent.

Carbon fiber is a threaded structure made with highly technological materials called composites, as the fibers are “composed” , i.e. joined together to another element, usually resin. Thousands of fibers are made into strands, which are “woven” into a carbon fibre matting, known as the “reinforcement”. The matting is carefully laid into a mould taking into account the desired shape, strength and finish required. The carbon fibre matting or reinforcement is then bonded with a different element, “the matrix” generally a polymer such as epoxy resin.

This method produces structures of exceptionally high strength to weight ratio – much stronger and approx 20% lighter than traditional GRP shells. Their mechanical resistance (against accidental impact), thermal insulation, resistance to temperature range and weight are also far superior to traditional GRP.

Textile

Fabric evaluation criteria

A very good fabric cannot be just waterproof (it would be unsuitable as a camping fabric), one of its' main properties must be breathability: Each square centimetre of fabric shall contribute to the natural change of air.

Fiberglass

Shells in fiberglass

Fiberglass is a specific fibre threaded fabric, impregnated with liquid resins or polyester, often known as GRP from the English “glass reinforced plastic” (GFK in German).

Carbon Fiber

| Details on carbon fiber | Details on carbon fiber |

|

|

Shells in carbon fiber

The innovative and exclusive production of carbon fiber shells enables us to realize an exceptionally strong, yet lightweight tent.

|

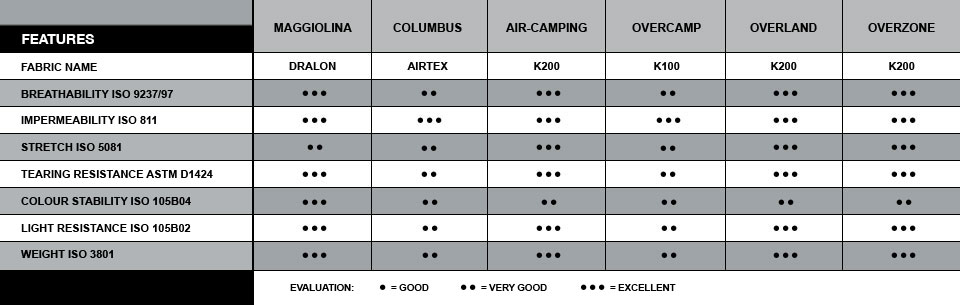

Fabric quality evaluation to ISO Standards: |

Fabric quality evaluation to ISO Standards |

Fabric evaluation criteria

A very good fabric cannot be just waterproof (it would be unsuitable as a camping fabric), one of its' main properties must be breathability: Each square centimetre of fabric shall contribute to the natural change of air. This characteristic allows to obtain a real weel-being condition that can only be assured by high transpiration and speed in water vapour transferring. This basic principle should be adhered to, especially in environments with small volumes of air, (such as a tent) to prevent condensation forming, and therefore, a heat reduction occurring within. By allowing a natural through flow of air, containing moisture, generated by the occupants of the tent maximum comfort can be achieved.

To scientifically evaluate a fabrics qualities, subject to its uses, we have to consider the following:

| 1. | The ratio between impermeability (maximum column of water the fabric is resistant to, according to ISO 811) and breathability (air permeability according to ISO 9237), calculated with reference to dimensions and inner volumes of the tents (habitable area) and area (in square metres) of the textile surface: basic criteria for a healthy environment. |

|

||||||||||

| 2. | Specific purpose of the fabric: for example the tents roof or side walls, including stresses and movement the fabrics are subject to as well as weather and climatic influences. | |||||||||||

| 3. | Stretch (ISO 5081), and tear-resistance (ASTM D1424) | |||||||||||

How to check the fabric is breathable

|

|

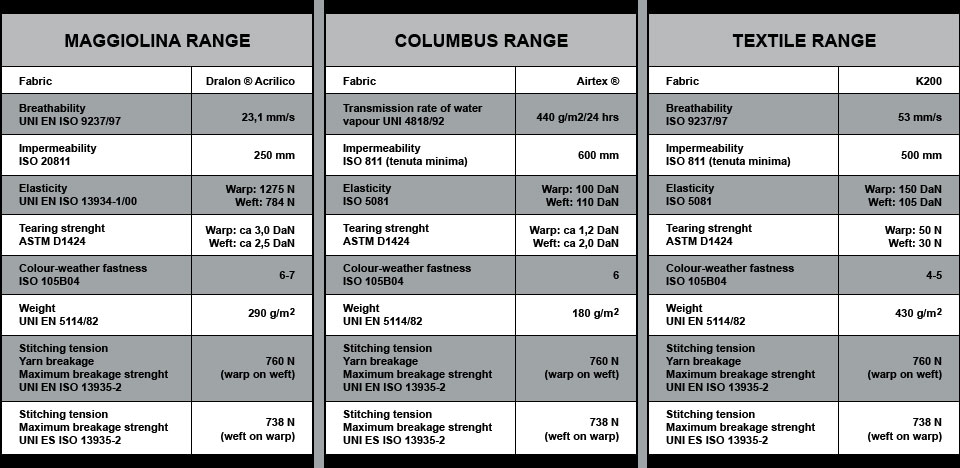

| Breathability Dralon Fabric: mm/s 23,1 K100-K200 Fabric: mm/s 9,3 |

Water vapour transmission Airtex Fabric: g/m²/24hrs: 440 |

Many fabric suppliers say their fabric is breathable, but to make sure it is, use the following procedure. Approach the tent and press a small area of fabric over your mouth. When breathing out if you feel the air flow in the palm of your hand, the fabric is considered breathable.

Another very important factor is the transmission rate of the water vapour through the fabric, which should not be lower than 350 g/m²/24hrs. Only the high breathability and/or the excellent water vapour transmission rate can effectively limit moisture forming inside the tent, thus keeping your environment fresh and healthy. Therefore, choose carefully!

Autohome Textile Characteristics

Textile

Fabric evaluation criteria

A very good fabric cannot be just waterproof (it would be unsuitable as a camping fabric), one of its' main properties must be breathability: Each square centimetre of fabric shall contribute to the natural change of air.

Carbon Fiber

| Details on carbon fiber | Details on carbon fiber |

|

|

Shells in carbon fiber

The innovative and exclusive production of carbon fiber shells enables us to realize an exceptionally strong, yet lightweight tent.